Introduction

Steel cord conveyor belts are vital for heavy-duty applications, offering exceptional strength and durability. These high-performance belts are crucial in industries like mining, construction, and manufacturing, where materials are transported over long distances.

In this article, we will explore the concept of elongation in steel cord conveyor belts. You will learn how elongation affects efficiency, performance, and system longevity.

Understanding Elongation: A Key Factor in Conveyor Belt Performance

Defining Elongation in Conveyor Belts

Elongation refers to how much a conveyor belt stretches when it is subjected to tension or load. In simple terms, it’s the increase in length that the belt undergoes while transporting materials. Steel cord conveyor belts are designed to limit elongation, usually to less than 0.25% under full load, which makes them more reliable and efficient compared to textile belts.

While textile belts may experience elongation up to 4%, steel cord belts maintain their shape and size even under heavy stress. This property is critical in operations where materials need to be conveyed across long distances or on steep inclines. The minimal elongation ensures that the belt remains stable and aligned throughout its operation.

How Elongation is Measured

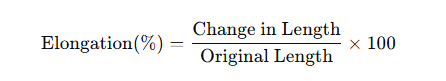

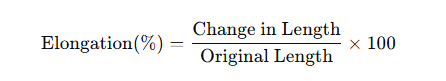

To measure elongation, a tensile test is commonly used. During this process, a sample of the steel cord conveyor belt is placed under a defined load, and its length is measured before and after the load is applied. The formula for calculating elongation is:

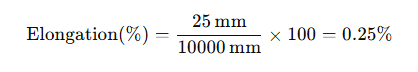

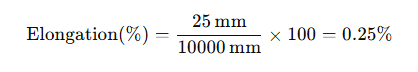

This provides the percentage of elongation experienced by the belt under tension. For instance, if a steel cord belt with an original length of 10 meters stretches by 25 millimeters under load, the elongation would be:

This minimal elongation is ideal for heavy-duty operations, as it ensures that the belt maintains its shape and tension, minimizing misalignment and wear. Steel cord belts can handle much higher tension without significant stretching, in contrast to textile belts, which can experience up to 4% elongation under similar conditions. This difference is crucial in applications where precision and long-distance transport are required, such as mining or material handling on steep inclines.

Why Elongation Matters in Steel Cord Conveyor Belts

Elongation significantly affects the operational efficiency of the conveyor system. When a belt stretches excessively, it can lead to misalignment, increased tension, and faster wear of system components. These issues can result in costly maintenance, downtime, and increased energy consumption.

By minimizing elongation, a steel cord conveyor belt maintains tension more consistently, ensuring smooth, continuous operation. It reduces the frequency of re-tensioning and adjustments, which are both time-consuming and costly. This stability is especially important in industries that require high precision, such as bulk material handling in ports or mines, where precise alignment and constant tension are essential for effective transport.

How to Measure Elongation in Steel Cord Belts

The elongation of a steel cord conveyor belt is typically measured using a tensile test, which involves applying a load to the belt and measuring the amount of stretch before it reaches its breaking point. This test is critical in ensuring the belt meets the required performance standards for its specific application.

Steel cord belts are designed to maintain an elongation rate of less than 0.25% under full load, a key distinguishing factor when compared to other types of conveyor belts. This minimal elongation ensures that the steel cord conveyor belt retains its structural integrity under heavy-duty conditions, offering consistent performance throughout its service life.

Core Features of Steel Cord Conveyor Belts That Influence Elongation

High Tensile Strength and Its Impact on Elongation

One of the main advantages of steel cord conveyor belts is their high tensile strength, which is the maximum load they can bear without breaking. The higher the tensile strength of the belt, the lower the elongation. This relationship is key to maintaining the belt’s integrity and minimizing stretching under load.

The steel cords within the belt structure provide excellent tensile strength, making the conveyor belt capable of handling heavy-duty applications. Whether it's transporting bulk materials across long distances or over steep inclines, the high tensile strength of the steel cord belt prevents excessive elongation, ensuring that the system remains stable and efficient.

Benefits of Low Elongation for Precision and Efficiency

Low elongation plays a crucial role in improving the precision and efficiency of conveyor systems. With minimal elongation, the belt maintains a more consistent length during operation, ensuring smooth material flow and reducing the risk of misalignment. This results in a more efficient material handling process, particularly in high-speed systems where maintaining a constant tension is essential.

The efficiency gains from low elongation also extend to energy savings. When a belt doesn’t stretch significantly, the system requires less energy to maintain tension, contributing to lower operational costs. This is especially beneficial for industries looking to reduce their energy consumption while maintaining high system performance.

The Role of Steel Cords in Minimizing Elongation

The steel cords embedded within the belt are the primary factor in minimizing elongation. These cords provide exceptional tensile strength and resistance to stretching, ensuring that the belt maintains its shape even under high load conditions.

The cords are typically arranged in parallel lines, running along the length of the belt. This configuration allows the load to be distributed evenly, preventing localized elongation and enhancing the belt's overall stability. This arrangement is key to the durability and performance of steel cord belts, particularly when used in heavy-duty, long-distance applications.

The Impact of Elongation on Steel Cord Conveyor Belt Performance

Problems Caused by Excessive Elongation in Conveyor Belts

Excessive elongation can create several operational problems. Misalignment is one of the most common issues, as an excessively stretched belt can drift off track, leading to additional wear on pulleys and rollers. Misalignment can also increase the risk of materials spilling, reducing the overall efficiency of the system.

Increased tensioning requirements are another problem caused by elongation. As the belt stretches, more force is needed to maintain tension, which leads to increased wear and more frequent adjustments. Over time, this added strain can accelerate the deterioration of the belt, resulting in higher maintenance costs and more frequent replacements.

Why Minimizing Elongation Ensures Maximum Conveyor Belt Efficiency

To achieve maximum efficiency, it is essential for steel cord conveyor belts to have minimal elongation. The ideal elongation rate for these belts is typically ≤ 0.25% under full load, which ensures that the system remains stable, with consistent tension across the length of the belt.

Maintaining minimal elongation leads to smoother operations, with fewer adjustments needed. This results in lower maintenance costs, fewer system failures, and improved system uptime. The stability provided by low elongation also helps extend the belt's lifespan, ensuring long-term performance and reduced downtime.

Design Considerations for Reducing Elongation in Steel Cord Belts

Several design factors help minimize elongation in steel cord conveyor belts. These include the choice of core material, the diameter and spacing of the steel cords, and the type of rubber cover used.

The core material, typically made from steel, provides the necessary strength and resistance to elongation. The diameter and spacing of the steel cords also influence the belt’s flexibility and elongation. By using smaller diameters and closer spacing, the belt can better resist stretching under load.

In addition, the rubber covers that protect the steel cords play a role in reducing elongation. The right combination of rubber material and thickness can provide extra resistance to elongation, helping the belt perform optimally under load.

| Design Feature | Effect on Elongation | Impact on Belt Performance |

| Core Material (Steel) | Reduces elongation significantly | Provides high tensile strength, minimizes stretching |

| Cord Diameter | Smaller diameters reduce elongation | Increases resistance to stretching under heavy loads |

| Cord Spacing | Closer spacing limits elongation | Enhances load distribution, prevents uneven stretching |

| Rubber Cover Thickness | Thicker covers help reduce elongation | Protects cords and enhances belt durability |

Comparing Steel Cord Conveyor Belts with Other Belt Types: Elongation and More

Elongation Differences Between Steel Cord and Textile Conveyor Belts

When compared to textile conveyor belts, steel cord belts offer a much lower elongation rate. Textile belts can elongate by up to 4% under load, while steel cord belts typically stretch by less than 0.25%. This significant difference makes steel cord belts the preferred choice for heavy-duty, high-capacity, and long-distance applications.

Steel cord belts also provide greater tensile strength, allowing them to handle heavier loads over longer distances. In contrast, textile belts, with their lower tensile strength, are less capable of handling such loads without significant elongation, making them less suitable for demanding applications.

Elongation Comparison Between Steel Cord and Textile Conveyor Belts

| Conveyor Belt Type | Elongation Rate Under Full Load | Typical Applications | Advantages |

| Steel Cord Conveyor Belt | ≤ 0.25% | Heavy-duty, long-distance transport | Minimal elongation, high tensile strength, reliable under heavy loads |

| Textile Conveyor Belt | Up to 4% | General-purpose, shorter distances | More flexibility, cheaper for light-duty applications |

How Low Elongation Contributes to Greater System Efficiency

Low elongation contributes to greater system efficiency by reducing the amount of stretch that occurs during operation. With minimal elongation, the system uses less energy to maintain tension, which results in lower operational costs.

Furthermore, low elongation allows the conveyor system to run at higher speeds without the risk of the belt becoming misaligned or experiencing excessive wear. This capability improves throughput and overall system performance, making steel cord conveyor belts a more efficient choice compared to textile belts.

Key Applications of Steel Cord Conveyor Belts: Elongation in Practice

Long-Distance and High-Lift Conveying Systems

Steel cord conveyor belts with low elongation are ideal for long-distance and high-lift systems. These belts can transport bulk materials over great distances without significant stretching, maintaining consistent tension and ensuring smooth, efficient operation.

For example, in mining or port operations, where large quantities of materials need to be moved quickly and efficiently, steel cord belts help maintain the necessary tension to ensure smooth operation. The low elongation of steel cord belts ensures that they remain accurate and effective throughout the entire transport process.

Using Steel Cord Conveyor Belts in Harsh Environments and Heavy Loads

Steel cord conveyor belts excel in harsh environments where heavy loads and extreme conditions are common. Whether used in mining, quarries, or cement plants, these belts can handle the stresses of transporting heavy materials over long distances without excessive elongation.

The minimal elongation of steel cord belts also makes them more resistant to damage from temperature fluctuations, abrasive materials, and other environmental factors, ensuring greater reliability and fewer breakdowns.

Steel Cord Belts in High-Speed Conveying Systems

In high-speed conveying systems, where precision and speed are critical, steel cord conveyor belts are the optimal choice. Their low elongation ensures the belts maintain their shape and tension, even at high speeds. Unlike textile belts, which can stretch under such conditions, steel cord belts offer greater stability, preventing misalignment and ensuring smooth, continuous operation. This makes them ideal for industries like airports and automated warehouses, where materials need to be transported quickly and accurately over long distances. Their durability and resistance to elongation also reduce maintenance needs, making them more efficient in high-speed applications.

Conclusion

The elongation of a steel cord conveyor belt plays a crucial role in its efficiency and performance. Low elongation improves system stability, reduces downtime, and ensures smoother operation. This characteristic is especially important in heavy-duty applications. By choosing the right steel cord conveyor belt with minimal elongation, businesses can optimize performance while cutting maintenance and operational costs.

Shandong Longli Blets Co.,Ltd provides high-quality steel cord conveyor belts that are designed for durability and minimal elongation. Their products offer value by ensuring reliable and efficient material transport for industries with demanding operational needs.

FAQ

Q: What is the elongation of a steel cord conveyor belt?

A: Elongation refers to how much a steel cord conveyor belt stretches under load. Steel cord belts typically have minimal elongation, usually less than 0.25% under full load, making them ideal for heavy-duty applications where stability and efficiency are crucial.

Q: Why is low elongation important for steel cord conveyor belts?

A: Low elongation ensures that steel cord conveyor belts maintain consistent tension, reducing the risk of misalignment and preventing downtime. It enhances system stability, making the belt more reliable in high-speed, heavy-duty operations.

Q: How does elongation affect the performance of a steel cord conveyor belt?

A: Excessive elongation can cause misalignment, increase maintenance needs, and reduce efficiency. Steel cord conveyor belts with low elongation perform better by maintaining shape and tension, minimizing the need for re-tensioning.

Q: Can a steel cord conveyor belt be used in high-speed applications?

A: Yes, steel cord conveyor belts are ideal for high-speed applications due to their low elongation. This ensures that the belt maintains proper tension and alignment, providing reliable performance even at high speeds.

Q: How is elongation measured in a steel cord conveyor belt?

A: Elongation is typically measured through a tensile test, where a load is applied to the steel cord conveyor belt and the amount of stretch is recorded. This test helps ensure the belt’s performance under heavy loads.

Q: How does the cost of a steel cord conveyor belt compare to other types?

A: While steel cord conveyor belts tend to be more expensive than textile belts, their durability, minimal elongation, and ability to handle heavy loads over long distances make them a cost-effective choice in the long run for high-demand applications.