Introduction

Steel Cord Conveyor Belts are the backbone of many heavy-duty industries. They are built to withstand extreme conditions where other belts fail. Whether transporting coal, ore, or cement, these belts handle the toughest tasks with ease.

In this article, we will dive into the key features and benefits of steel cord conveyor belts. You will learn how their unique design makes them ideal for long-distance, high-capacity operations. By the end, you'll have a clear understanding of why steel cord belts are essential for industries requiring reliable, high-performance transport solutions.

What Sets Steel Cord Conveyor Belts Apart from Other Belt Types?

Core Structure and Components of Steel Cord Belts

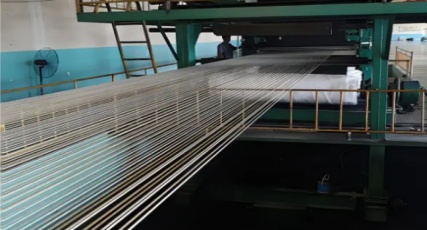

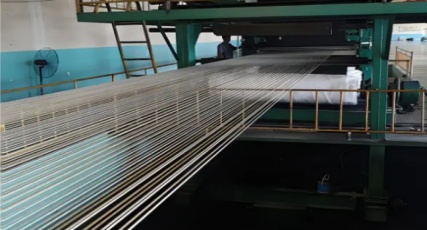

A steel cord conveyor belt is a durable type of rubber belt reinforced with high-tensile steel cords. These steel cords run parallel along the belt’s length, embedded within the rubber, which provides exceptional strength and long-lasting durability compared to conventional fabric belts. This distinctive design enables the belt to handle significantly heavier loads and greater distances without stretching or breaking down.

Unlike fabric belts, which are constructed with synthetic fibers prone to wear and tear under heavy loads, steel cord conveyor belts are made for tough environments that demand strength and resilience. Their ability to endure extreme pressure, impacts, and minimal elongation makes them an ideal solution for industries that deal with heavy bulk materials or require transportation over extended distances, where fabric belts would typically fail.

Distinctive Features of Steel Cord Conveyor Belts

Steel cord conveyor belts are known for several distinctive features, making them suitable for demanding applications. These features enhance performance and reliability, which are critical for industries that rely on uninterrupted operations:

High Tensile Strength: A steel cord belt offers much higher tensile strength, making it perfect for moving heavy loads like coal, ore, gravel, and other bulk materials. The strength of the belt ensures it can endure intense pressure and weight typical in industrial transport systems.

Minimal Elongation: Steel cord belts stretch less than 0.25% under full load, meaning they require fewer adjustments during operation. This characteristic leads to fewer disruptions, resulting in a more efficient system.

Impact Resistance: Steel cords are designed to resist impacts from falling heavy materials, making the belts ideal for environments where sharp objects or heavy loads could damage standard fabric belts. This resistance ensures the belt remains functional and reliable even in the harshest working conditions.

These attributes combine to make steel cord conveyor belts the preferred choice for long-distance, high-load applications. Their ability to deliver increased efficiency, safety, and reliability makes them essential for industries requiring dependable transport solutions.

The Construction Process Behind Steel Cord Conveyor Belts

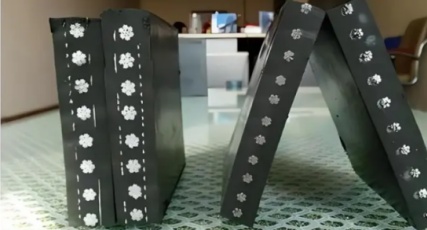

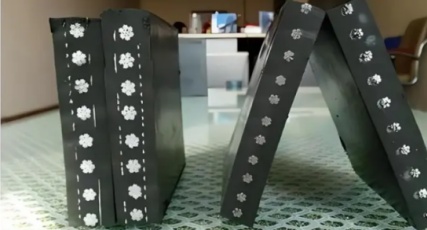

Steel Cord Core: The Structural Backbone

The steel cord core is what gives the conveyor belt its strength. High-tensile steel cords run longitudinally along the belt’s length, providing structural integrity. Typically made from high-carbon steel, the cords are coated with either zinc or brass to prevent corrosion. This ensures that the cords stay strong, even in environments exposed to moisture, heat, or chemicals.

The cords are arranged in parallel, which enhances the belt’s load-bearing capacity. For long-distance use, multi-strand designs are often utilized to improve flexibility, allowing the belt to handle continuous bending as it moves around pulleys. These designs reduce the wear on the belt and help maintain its integrity, even under high-stress conditions that would cause other belts to fail.

Protective Bonding and Cushion Layers for Durability

Steel cord conveyor belts are designed with bonding and cushion layers that protect the steel cords. The bonding rubber keeps the cords in place while allowing the belt to remain flexible, ensuring that the cords do not shift under heavy loads. This ensures that the belt can handle heavy materials without the risk of deformations or breakage.

Cushion layers are placed beneath the cover rubber to absorb impacts from falling materials. These layers prevent damage to the steel cords, preserving the belt’s structural integrity. Additionally, cushion layers reduce wear and tear, extending the belt's lifespan. The protective layers are vital for industries like mining, where heavy materials are moved regularly and belt failure can result in significant operational delays.

External Rubber Cover: Protection from Environmental Damage

The external rubber covers are what shield the steel cord core from external wear and environmental damage. These covers vary in thickness depending on the specific application. For example, mining operations may require thicker covers to withstand high abrasion, while cement plants need heat-resistant covers to protect against molten materials.

Typically, the cover thickness ranges from 6 mm to 12 mm, with top covers being thicker to absorb impacts from dropped materials, while the bottom covers are thinner, as they only need to handle friction from idlers. The rubber cover serves a multi-faceted role, offering protection against physical damage, weathering, and exposure to chemicals, all of which are essential to maintaining the belt’s longevity and functionality.

| Component | Description |

| Steel Cord Core | High-tensile steel cords embedded in rubber to provide strength and durability. |

| Bonding Layer | Rubber layer holding the steel cords in place, providing flexibility and preventing shifting. |

| Cushion Layer | Protects steel cords from impacts, absorbing shock and reducing wear. |

| External Rubber Cover | Shields the core from physical damage, heat, and chemicals. |

Key Industries Using Steel Cord Conveyor Belts

Mining and Ore Transport: Essential for Heavy Loads

Steel cord conveyor belts are widely used in mining for the transportation of bulk materials such as coal, ore, and gravel. Mining environments are often harsh, with conveyor belts subject to extreme loads, impacts, and even exposure to chemicals. Steel cord belts are favored in these industries because of their high tensile strength and resistance to damage from sharp objects and abrasive materials.

These belts can span long distances—up to several kilometers in some cases—making them ideal for open-pit mining operations, where materials need to be moved across vast areas. Additionally, steel cord belts’ resilience to wear and tear reduces the frequency of repairs and replacements, contributing to cost savings and more efficient operations.

Power Plants and Steel Mills: Handling Extreme Conditions

Power plants need a continuous supply of raw materials, especially coal, to keep their operations running smoothly. Steel cord conveyor belts are used to transport large amounts of coal from mines to power plants, often in high-temperature conditions. Their ability to withstand heat and resist wear is crucial in these applications, where extreme temperatures would cause fabric belts to degrade quickly.

Similarly, steel mills depend on steel cord conveyor belts to move scrap metal, molten slag, and other heavy materials. These belts provide the necessary strength and durability to cope with the harsh conditions of steel production, such as high temperatures and abrasive materials. Steel cord belts ensure uninterrupted material handling, which is essential for the continuous operation of these industries.

Ports and Terminals: Transporting Bulk Cargo

Steel cord belts are also used extensively in port operations, where they are tasked with transporting bulk cargo such as grains, coal, and metal ores. The belts are often exposed to saltwater in these environments, which can quickly corrode the steel cords if not properly coated. Brass-coated steel cords and molded edge seals help protect the belts from the corrosive effects of saltwater, ensuring longevity and optimal performance.

Moreover, the heavy-duty nature of steel cord belts makes them perfect for the high-stress conditions in ports and terminals. These belts can handle significant loads without failure, which is critical for industries where transport speed and reliability are essential.

Manufacturing and Heavy Industry: Durability in Demanding Environments

In manufacturing sectors like cement production and chemical processing, steel cord conveyor belts are used to move raw materials and finished products over long distances. These industries often deal with high temperatures, abrasive substances, and heavy loads, which require the strength and durability provided by steel cord belts.

In cement plants, for example, the belts must endure high temperatures as they transport materials like clinker, which can reach extremely hot temperatures. Steel cord belts with heat-resistant covers are perfect for this task, offering reliable material handling in challenging conditions.

| Industry | Application | Challenges Addressed |

| Mining | Transporting coal, ore, and gravel over long distances. | Heavy loads, harsh environments, and extreme abrasion. |

| Power Plants | Moving coal and other materials to power generation facilities. | High-temperature environments, extreme wear. |

| Steel Mills | Conveying scrap metal, slag, and molten materials. | Heat resistance, heavy-duty transport under abrasive conditions. |

| Ports and Terminals | Transporting bulk cargo like grains, coal, and metal ores. | Corrosion from saltwater, heavy material handling. |

| Manufacturing | Moving raw materials and finished products in plants like cement production. | High-temperature, abrasive materials. |

Advantages of Steel Cord Conveyor Belts

Enhanced Efficiency and Load Handling Capacity

Steel cord conveyor belts can handle heavier loads and longer distances than fabric belts, significantly increasing operational efficiency. Their minimal elongation ensures consistent tension and performance over time, reducing the need for frequent adjustments. This consistency allows businesses to maintain smoother operations with fewer interruptions.

Additionally, the strength of steel cord belts means they can support longer, higher-capacity conveyor systems. This reduces the need for multiple transfer points, streamlining the material-handling process and reducing the overall number of conveyors required. This results in both cost savings and improved operational efficiency.

Longevity and Durability: A Long-Term Investment

Steel cord conveyor belts are known for their durability and longevity. They last much longer than fabric belts, even in harsh environments. Their ability to resist impact, abrasion, and extreme temperatures ensures they are suitable for demanding applications, reducing the need for frequent replacements and costly repairs.

The durability of steel cord belts contributes to reduced downtime and maintenance costs, making them a wise long-term investment for businesses. Their extended lifespan also ensures that companies can continue to operate efficiently without worrying about frequent belt replacements.

Safety Features and Resistance to Harsh Conditions

Steel cord conveyor belts are designed to meet stringent safety standards, which is especially important in hazardous environments. These belts are often flame-retardant, anti-static, and resistant to chemicals, making them ideal for use in industries such as mining, power generation, and chemical processing, where the risk of fire, static buildup, or chemical exposure is high.

In high-risk environments like mining and cement production, where materials can be hazardous or high-temperature, the safety features of steel cord belts are essential. They help minimize risks to workers and ensure that operations continue safely and without disruption.

Maintenance and Splicing of Steel Cord Conveyor Belts

Correct Splicing Methods for Longevity

Proper splicing is critical for maintaining the integrity of steel cord conveyor belts. If the splicing is done incorrectly, it can weaken the belt and lead to premature failure. The correct procedure involves carefully aligning the cords, applying bonding materials, and using heat or cold vulcanization to ensure a strong, lasting joint.

Splicing the belt correctly also involves conducting strength tests to ensure the splice is as strong as the rest of the belt. Well-spliced belts can last as long as the original belt, minimizing downtime and reducing the need for frequent repairs or replacements.

Routine Maintenance for Extended Belt Life

Routine maintenance and timely repairs can greatly extend the life of steel cord belts. It’s essential to inspect belts regularly for signs of wear, especially at splice points and areas subjected to high impacts. Following the manufacturer's guidelines for maintenance and repair can minimize downtime and help keep the conveyor systems running smoothly.

Regular cleaning, lubrication, and proper belt tensioning also help ensure that the belt remains in good condition. Proper maintenance will extend the service life of the belt, keeping it efficient and minimizing costly disruptions in operations.

Conclusion

Steel cord conveyor belts are essential for industries dealing with heavy loads and long-distance transport. Their strength, durability, and resistance to harsh conditions make them the top choice in sectors like mining, power generation, ports, and manufacturing. By understanding the design, benefits, and maintenance needs, businesses can select the right steel cord conveyor belt, ensuring reduced downtime and enhanced productivity.

For those seeking reliable and high-performance conveyor belts, Shandong Longli Blets Co.,Ltd offers products with unmatched quality and service. Their steel cord conveyor belts provide exceptional value, delivering consistent performance in demanding environments.

FAQ

Q: What is a steel cord conveyor belt?

A: A steel cord conveyor belt is a type of rubber belt reinforced with high-tensile steel cords, designed for heavy-duty applications. It offers strength, durability, and resistance to extreme conditions, making it ideal for industries like mining, power generation, and manufacturing.

Q: How does a steel cord conveyor belt work?

A: Steel cord conveyor belts operate by using steel cords embedded within the rubber, providing strength and minimal elongation. This construction allows the belt to carry heavy loads over long distances with minimal wear.

Q: Why should I choose a steel cord conveyor belt over a fabric belt?

A: Steel cord conveyor belts are much stronger and more durable than fabric belts. They can handle heavier loads and longer distances, making them perfect for industries that require reliability in harsh conditions.

Q: What are the advantages of using a steel cord conveyor belt?

A: The advantages include high tensile strength, minimal elongation, impact resistance, and longer operational life. These features help reduce downtime and maintenance costs, offering long-term value for industries with demanding transportation needs.

Q: How much does a steel cord conveyor belt cost?

A: The cost of a steel cord conveyor belt varies depending on factors like length, width, and specific requirements. Generally, they are more expensive than fabric belts due to their durability and superior performance.

Q: How do I maintain a steel cord conveyor belt?

A: Regular inspections, proper splicing techniques, and cleaning are essential for maintaining a steel cord conveyor belt. It’s important to ensure proper tension and check for wear or damage to avoid costly repairs.

Q: Can steel cord conveyor belts be used in extreme temperatures?

A: Yes, steel cord conveyor belts are designed to withstand extreme temperatures. They are commonly used in high-temperature environments like steel mills and power plants, with specialized covers for added protection.