In modern port and terminal operations, efficiency, safety, and reliability are paramount. From bulk cargo to container handling, materials must be transported swiftly and safely to keep operations running smoothly. One of the most critical components in this process is the steel cord conveyor belt, a robust and durable solution designed to handle heavy loads, long distances, and challenging operational conditions. This article explores the role of steel cord conveyor belts in ports and terminals, their advantages, key design features, and why they are increasingly preferred in maritime logistics.

1. Understanding Steel Cord Conveyor Belts

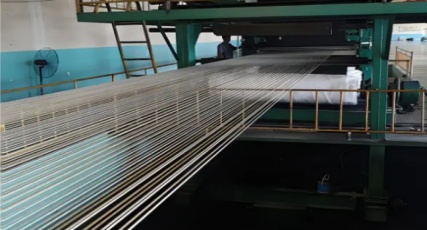

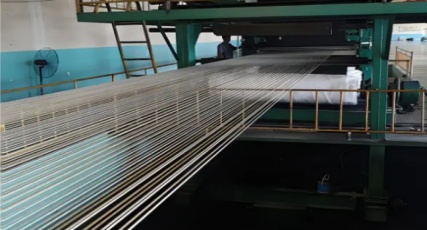

Steel cord conveyor belts are industrial-grade belts reinforced with high-tensile steel cords embedded longitudinally within the belt carcass. Unlike traditional fabric belts, which rely on layers of synthetic material, steel cord belts utilize steel reinforcement to provide exceptional strength, minimal elongation, and superior load-carrying capacity.

Structure of Steel Cord Conveyor Belts

A typical steel cord conveyor belt consists of:

Carcass Layer: Contains the high-strength steel cords, providing the primary tensile strength.

Rubber Covers: The top and bottom layers of the belt are made of abrasion-resistant rubber, protecting the steel cords and enhancing grip and durability.

Skim Layers: Thin rubber layers cover the steel cords to prevent direct contact with cargo or pulley components.

This structure makes steel cord belts ideal for long-distance, heavy-load, and high-speed conveyor applications, especially in ports where bulk cargo handling is continuous and intense.

2. Why Steel Cord Conveyor Belts Are Ideal for Ports and Terminals

Ports and terminals are some of the most dynamic and challenging environments for material handling systems. They must accommodate large volumes of cargo, varying weights, diverse materials, and continuous operations, often in harsh outdoor conditions. To meet these demands, steel cord conveyor belts have become an essential component in modern port logistics. Their combination of strength, durability, and adaptability makes them ideal for transporting goods safely and efficiently.

High Load Capacity

One of the most critical advantages of steel cord conveyor belts is their exceptional load-bearing capacity. In ports, materials such as coal, ores, grains, cement, and containerized goods can be extremely heavy. Unlike fabric or textile belts, steel cord belts are reinforced with high-tensile steel cables embedded longitudinally in the belt carcass.

This reinforcement allows them to support thousands of tons of material daily without excessive stretching or sagging. For instance, bulk coal terminals rely on steel cord belts to transport heavy coal loads from unloading stations to storage yards. The belts’ high load capacity ensures that operations remain smooth even when transporting large cargo volumes continuously, reducing delays and bottlenecks.

Additionally, the low elongation properties of steel cord belts mean that port operators do not need to constantly adjust belt tension, as is often necessary with traditional textile belts. This reliability is critical for large-scale operations where any downtime can cause significant economic losses.

Long-Distance Transport

Many modern port facilities span vast areas, often covering hundreds or even thousands of meters of conveyor lines. Whether moving cargo from docks to storage yards or connecting different terminals, long-distance transport requires belts that maintain their structural integrity over extended runs.

Steel cord conveyor belts are specifically engineered for this purpose. Their high-strength steel cords resist stretching, maintaining consistent tension across long distances. This ensures that materials are transported smoothly without sagging or deviation, which can cause spillage, damage to cargo, or mechanical stress on the conveyor system.

Ports handling multiple commodities simultaneously benefit from steel cord belts because they can handle continuous operation for hours or days, reducing the need for frequent maintenance or replacement. This long-distance capability also makes them ideal for automated conveyor systems and stacker-reclaimer setups in bulk material terminals.

Enhanced Durability and Longevity

Durability is another key reason steel cord conveyor belts are widely adopted in port operations. Port environments can be harsh: belts may be exposed to abrasive materials, sharp or uneven cargo, high operational temperatures, and exposure to water, oils, or chemicals. Steel cord belts are designed to withstand these challenges.

The rubber covers protect the steel cords while providing resistance against abrasion, punctures, and wear. Specialized top-cover compounds handle friction from bulk materials, while bottom covers endure constant contact with pulleys, idlers, and rollers.

Additionally, some steel cord belts are available in flame-resistant or heat-resistant versions, which is particularly valuable for ports handling combustible or high-temperature materials like coal or cement clinker. The belts’ enhanced durability translates to longer service life, fewer replacements, and lower maintenance costs, making them a cost-effective choice over the long term.

Increased Operational Efficiency

Operational efficiency is critical in ports, where cargo throughput and turnaround times directly impact profitability. Steel cord conveyor belts contribute significantly to efficiency in several ways:

Rapid Cargo Transport: They can operate at high speeds, ensuring continuous movement of bulk materials from ships to storage or loading points.

Steep Inclines and Declines: Steel cord belts are capable of handling steep gradients without slippage, allowing flexible conveyor layout designs.

Minimized Downtime: Their durability and resistance to wear reduce operational interruptions caused by maintenance or unexpected failures.

Improved Safety: The robust construction reduces the risk of belt breakage or cargo spillage, enhancing workplace safety for operators.

For example, in a container terminal, steel cord belts can efficiently move containers from quay cranes to automated stacking cranes, reducing handling time and increasing the throughput of ships. Similarly, in bulk cargo operations, the reliability of steel cord belts allows stackers and reclaimers to operate continuously without frequent belt adjustments, improving overall terminal productivity.

3. Key Design Features for Port Operations

Steel cord conveyor belts used in ports incorporate specific features tailored to demanding environments:

High-Tensile Steel Cords

The steel cords act as the primary tensile structure, giving the belt strength and minimal elongation under heavy loads. This ensures consistent performance across long distances, even under continuous stress from heavy cargo.

Abrasion-Resistant Covers

The top and bottom rubber covers protect the cords and provide friction resistance. Specialized compounds are used to withstand sharp or heavy cargo, reduce wear, and extend belt life.

Flame-Resistant Options

Ports often handle materials prone to combustion, such as coal or fertilizers. Fire-resistant steel cord belts are designed to reduce the risk of belt ignition and enhance overall operational safety.

Modular Design and Customization

Steel cord belts can be customized in width, thickness, and rubber compound to suit specific operational needs. Terminals can choose belts based on cargo type, belt speed, environmental conditions, or even export requirements for specialized installations.

4. Applications in Ports and Terminals

Steel cord conveyor belts have wide applications, including:

Bulk Material Handling: Transporting coal, ores, grains, fertilizers, and cement from ships to storage yards.

Container Terminals: Moving containers efficiently between storage areas, cranes, and automated handling systems.

Stockpile Management: Connecting stackers and reclaimers for seamless pile management.

Loading and Unloading Ships: Ensuring smooth cargo transfer with minimal manual intervention.

Intermodal Operations: Linking ship-to-train or ship-to-truck systems for faster and safer logistics.

Their versatility and reliability make steel cord conveyor belts an indispensable asset in modern port infrastructure, ensuring high throughput, operational safety, and cost efficiency.

5. Advantages Over Fabric Conveyor Belts

While fabric conveyor belts have been used historically, steel cord belts offer clear advantages for demanding port operations:

Feature | Fabric Belt | Steel Cord Belt |

Load Capacity | Medium | Very High |

Long-Distance Performance | Limited | Excellent |

Elongation | High | Minimal |

Durability | Moderate | High |

Resistance to Harsh Conditions | Moderate | High |

Maintenance Frequency | Higher | Lower |

These benefits explain why many modern ports are upgrading to steel cord conveyor systems for efficiency, reliability, and long-term cost savings.

6. Maintenance and Operational Tips

To maximize the life of steel cord conveyor belts:

Regular Inspections: Check for wear, cracks, or damage to the rubber cover and steel cords.

Proper Alignment: Ensure pulleys and idlers are correctly aligned to prevent uneven wear or belt drift.

Tension Control: Maintain proper belt tension to avoid excessive elongation or slippage.

Cleaning: Remove debris, oil, or water from the belt surface to prevent premature wear.

Replace Worn Parts: Timely replacement of pulleys, rollers, and belt sections extends overall service life.

With proper maintenance, steel cord conveyor belts can serve efficiently for 10–15 years or more in port operations.

7. Conclusion

Steel cord conveyor belts are a cornerstone of modern port and terminal efficiency. Their high load capacity, durability, long-distance performance, and resistance to harsh conditions make them ideal for bulk material handling, container transport, and stockpile management. Ports relying on these belts benefit from faster operations, lower maintenance costs, and improved safety for personnel.

For port operators and logistics managers seeking reliable steel cord conveyor solutions, partnering with an experienced supplier is essential. Shandong Longli Belts Co., Ltd. offers high-quality, customizable steel cord conveyor belts designed specifically for port and terminal applications. Their products combine advanced engineering, long-lasting materials, and industry expertise to support efficient and safe cargo handling.

For more information or to explore tailored solutions, you can contact Shandong Longli Belts Co., Ltd., a trusted name in industrial conveyor technology.